Plastic Waste to 3D Printer Spool

Our research team led by Mr. Wisdom Eyo (a graduate of mechanical Engineering) has designed and built a working prototype 3D printer from locally available parts from electronic and plastic wastes. The equipment for production of filament for the 3D printer were also built and have proven efficient functionality ready for commercialization.

The prototypes comprise the following:

- Filament Extruder: This machine extrudes the raw material from recycled plastic waste or pellets to 3D printer filament

- Filament Spooler/Winder: This machine winds the extruded filament from the extruder automatically into rows and layers of filament spools

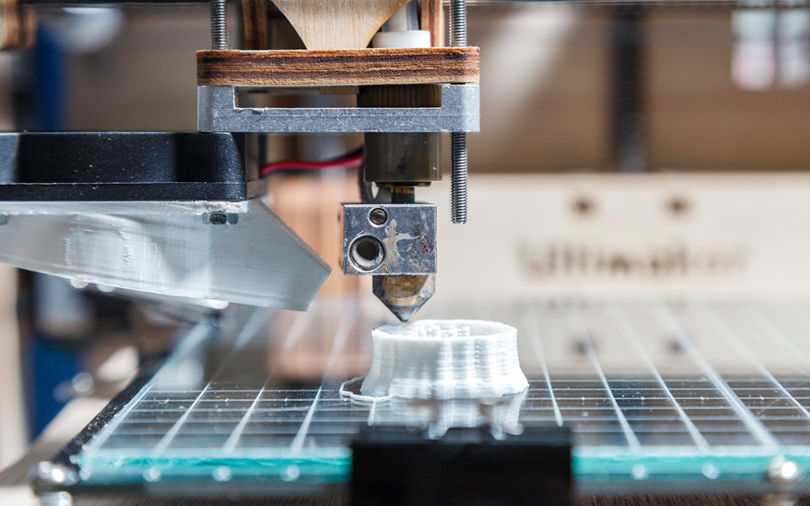

- 3D Printer: This is otherwise called the rapid prototyping machine, It is a computer controlled machine that takes the filament produced by the two machines above and uses it to print new physical objects in three dimensions from the CAD model of the object

We seek partnership to scale up these prototypes to facilitate 4th industrial revolution in Akwa Ibom State